Process Miracles

Unfortunately, that many business leaders fail to realize the value to be obtained through directing focus on company processes, therefore this paper aims to clarify some of the value that can be obtained through processes initiatives.

Preface

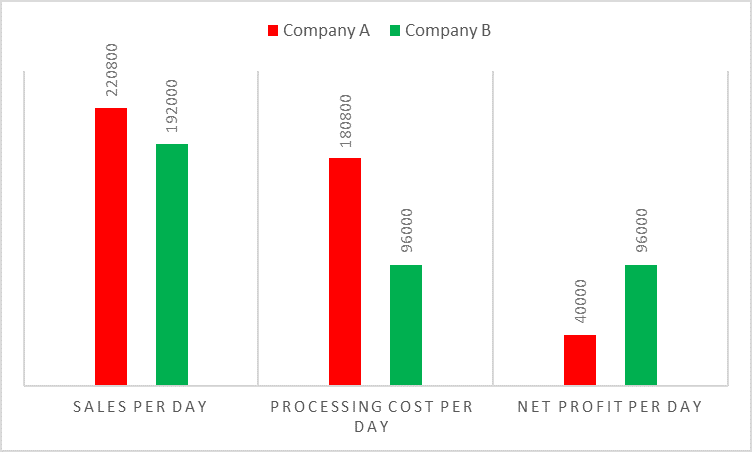

It is hard to believe that one company has the capacity to generate much more profit than its direct competitor although it employs half the quantity of staff of the said competitor. However, in fact, this could be a reality, as shown below:

| Employees | Produced products (per day) | |

| Company A | 1130 | 22080 |

| Company B | 600 | 19200 |

Assumptions applied to both companies:

- Staff working hours are 8 per day

- Employees’ pay per hour is 20 for each

- Product selling price is 10 per product

- Cost calculation is based on employees’ pay only

- Products are produced and sold on the same day (no inventory)

- They are using the same technology

As shown in the above chart, Company B is able to generate 96,000 in net profit as opposed to 40,000 generated by Company A.

As shown in the above chart, Company B is able to generate 96,000 in net profit as opposed to 40,000 generated by Company A.

Process experts would recognize at first glance that it illustrates that Company B adopts the lean manufacturing process. On the other hand, others might see the previous numbers as somewhat miraculous. Therefore, the purpose of this paper is to highlight how such results could be achieved through process improvement initiatives.

The assembly line

1In 1908, Henry Ford was able to sell a car at $825 which was considered an affordable option at the time. However, six years later, the company was able to drop the price much further to $360 resulting in the sale of 472,000 cars in that year. A highly strategic move as by 1918, half of all cars in the United States were Model Ts produced by the Ford company, as shown below.

While dropping the cost of its car to half the original price, Ford also astonished the world in 1914 by offering a $5 per day wage, which was more than double the rate that most of his workers were previously earning.

This initial success achieved by Ford was the result of the development of an assembly line mode of production adopted by the company in its factory in 1913, as shown below.

It was after Henry Ford had visualized the overall production process that he then proceeded to divide the process into smaller manageable activities. The individual steps were designed to operate in sync, thus speeding up the complete process, culminating in the whole idea of the assembly line.

It was after Henry Ford had visualized the overall production process that he then proceeded to divide the process into smaller manageable activities. The individual steps were designed to operate in sync, thus speeding up the complete process, culminating in the whole idea of the assembly line.

Japan’s economic miracle

It is generally considered that the economic recovery from any crises usually requires extensive time. This, however, did not appear to be the case with the Japanese economy after World War 2, a crisis still thought to be one of the worst the world has ever witnessed.

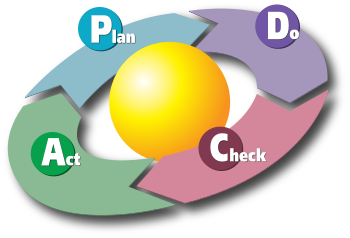

2By 1960, the Japanese industrial production index had reached 350%, said by experts to be miraculous. Such success undoubtedly requires a lot of political effort. Economic specialists also say that such results could not have been attained without the existence of Dr. Edwards Deming. Deming went to Japan in 1950 and began teaching his philosophy of the PDCA cycle to their leadership, a diagram of which is illustrated below.

Plan-Do-Check-Act (PDCA) is a method used in business to enable control and continuous improvement of processes and products.

Plan-Do-Check-Act (PDCA) is a method used in business to enable control and continuous improvement of processes and products.

3By 1980, the Japanese economy had become the second largest industrial power in the world, in contrast to the economy of the United States, which was in a recession at the time. This led U.S television network, NBC, to air the documentary “If Japan Can… Why Can’t We”. This propelled American leaders to action as they realized for the first time that the man behind the Japanese success was not only an American, but an inventive one at that. Thus, on American soil, the awareness of process and product improvement through the PDCA method became more widely accepted.

Motorola survival

4By 1970, every business which Motorola was engaged in, was already being targeted by the Japanese. At the time, Motorola, like many other American companies, was struggling to keep up with Japanese competition. The company’s customers were unhappy dealing with product defects and lack of customer support. Accordingly, Motorola’s management executives summoned the company engineers to a meeting. The aim was to devise a way to reduce the number of errors in their products before they were even shipped out of their factories.

Subsequently, Bill Smith, an engineer at Motorola at that time, came up with the Six Sigma methodology (measure, analyze, improve and control). Thus, started Motorola’s journey of key process documentation, aligning processes to customer requirements, and installing measurement systems to continually monitor and improve these processes.

As a result, Motorola’s performance improved instantly. However, even though they were doing well, analysis revealed that the Japanese were still way ahead of them due to the fact that they had been using similar technologies for much longer, as previously mentioned.

Even though Motorola were unable to beat the Japanese on this journey, they were however able to document more than $16 billion cost savings over eleven years through its adoption of the Six Sigma method.

Smooth merger

5In October 2008, Wells Fargo and Wachovia banks announced that they had agreed to merge. 6Before combination of the Wells and Wachovia trust operations, Paul Tazbaz, Wells Fargo’s enterprise architect, and Dave Watkins, Business Systems Consultant manager at Wells Fargo, collaborated to model and analyze existing processes while utilizing business process modeling and simulation tools.

Firstly, the processes were mapped out, revised, and added to if needed. Next, simulation and volume analysis were performed to figure out if the existing infrastructure (in terms of people and technology) could support increased volumes. If proven unfeasible, it would then have required the bank to add automation or staff.

Reliance on Business Process Analysis and Modeling, as well as BPMN (Business Process Model and Notation) in their standard processes, in addition to use of an advanced Business process management system, allowed the team to design an effective process. The innovative method enabled them to do something in one place and then deploy it in other places where the same process is being conducted.

Consequently, through such inventive ideas, the bank has saved nearly $100,000. Overall, the biggest benefit appears to have been in the capacity to mitigate the risks of such a large conversion. By the end of the project, as Watkins said, the gains were largely due to the fact that it was all done pretty seamlessly thus making it a project well worth embarking on.

Conclusion

Processes are seen as a set of documents that must exist in order to satisfy regulations or to govern the work of employees. However, it is perhaps unfortunate that many business leaders fail to realize the value to be obtained through directing focus on company processes. Attention made to improving company processes can mean reductions in costs and other progress for a business as seen in the success stories as told in this paper. 7To clarify, process, as stated in the Cambridge dictionary, means a series of actions that one takes in order to achieve a result. Accordingly, since the main goal of a company or organization is to prove its value and to deliver this quality to the customers, the processes undertaken by the company must be effective enough to achieve this aim.

Therefore, it can be concluded that the astounding results and statistics seen in the case studies of this paper highlight how efficient, or indeed, inefficient the performance of some companies is. Additionally, the figures also demonstrate that there is always scope for improvement in every business. Inefficiency in work production usually appears over time as every business is dynamic so the need to get a successful job done rapidly requires constant changes in work methods and the general performance of the business. Through this constant need for improvement, it is seen that many existing business processes are inefficient due to non-value adding activities being part of those processes. It has been shown that the removal of such unnecessary activities would thus lead to efficient business processes and astonishing results overall!

References

| 1. Henry Ford | 2. economy miracle |

| 3. if Japan can | 4. Motorola |

| 5. Wells Fargo | 6. Wells Fargo Used BPM |

| 7. Process meaning |